What is a COB LED technology ?

Say Goodbye to Pixel Grain! COB Display: the Next Generation Technology That Reshapes Visual Immersion

Have you ever been interrupted by the annoying "pixel graininess" in front of a large screen? Are you worried that a public screen will leave an unsightly black spot due to a damaged lamp bead? Or are you pursuing the visual shock of a nearly borderless and seamless picture? All these pain points are being resolved by a disruptive display technology: COB LED Display (Chip on Board LED Display).

If the traditional LED display is "from dots to surfaces", then the COB display is "from cores to surfaces". It is not only an upgrade of the packaging process, but also a revolution in visual experience.

The Achilles' Heel of Traditional Displays: the Limitations of SMD

At Present, Most Mainstream Indoor and Outdoor LED Displays Use SMD (Surface Mounted Device) Technology:

- Lamp Bead Manufacturing: First, the tiny red, green, and blue (R/G/B) LED chips are encapsulated in independent micro "lamp beads" with pins and plastic brackets.

- Mounting Into Screens: These R/G/B lamp beads are precisely welded on the PCB circuit board like SMD components to form pixels.

- Inherent Defects Appear:

- "Graininess" and "Moiré": The physical size of the lamp beads themselves (especially the bracket) and the black gaps (dead areas) between the pixels will produce obvious graininess and scan line moiré when viewed at close range, destroying the fineness and immersion of the picture.

- Fragility: Exposed lamp beads (especially the top lens) are extremely vulnerable to physical impact, static electricity (ESD), moisture, and dust, causing single or multiple lamp beads to fail and form permanent black spots or color spots.

- Protection limitations: The masks or fillers added to protect the lamp beads often affect the brightness, contrast or increase the thickness of the screen.

- Pixel density bottleneck: The physical size of the lamp beads and the patch accuracy limit the further miniaturization of the pixel pitch (Pitch), making it difficult to achieve ultra-high-density ultra-small pitch displays.

COB Display: Breaking Down the Whole Into Parts, Creating a Natural

COB Technology Directly Hits the Pain Points of SMD and Adopts a More Integrated and Protective Solution:

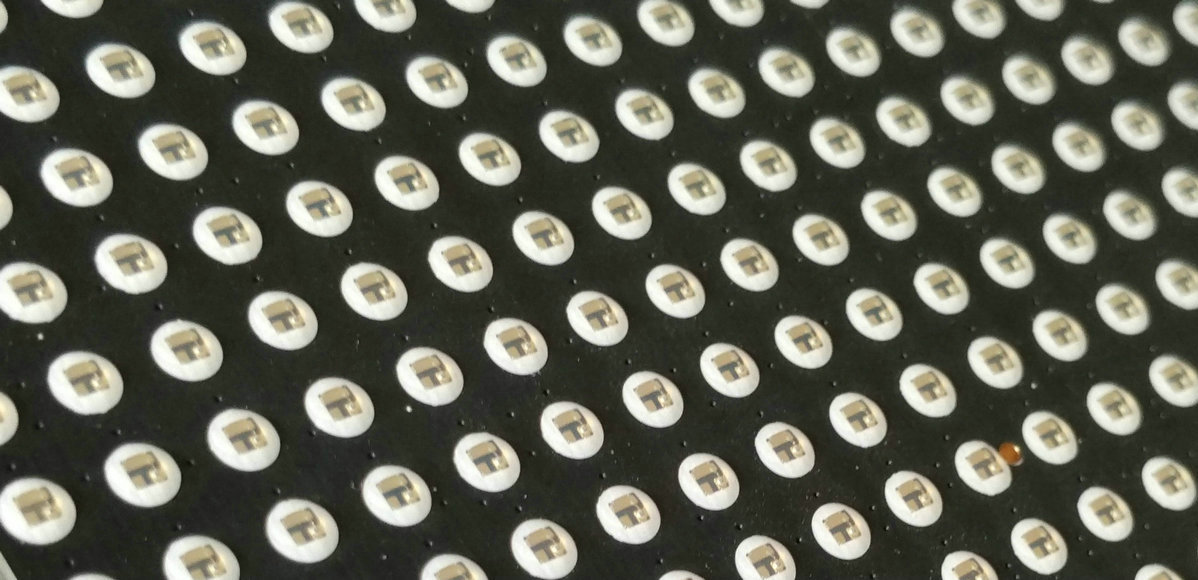

- Bare chip direct bonding: Directly and densely array-bond tiny R/G/B LED bare chips (unpackaged original chips) on a special PCB substrate (usually a high-precision, high-heat dissipation copper or aluminum substrate).

- Overall packaging: The dense LED chip array area on the entire PCB board is uniformly covered with a thick, transparent protective encapsulation glue (usually modified epoxy resin or organic silicone).

- Surface treatment: After the encapsulation glue is cured, a smooth, flat, and seamless luminous surface is formed. Blackening is usually performed to improve contrast.

COB display are no longer independent "lamp beads", but are composed of closely arranged R/G/B bare chips on the substrate and covered by an integral, solid "protective cover".

The Disruptive Advantages of COB Displays: Why is it the Future?

1.Extraordinary Visual Experience:

- Extremely delicate, no graininess: The bracket structure and black dead zone between dots of traditional lamp beads are eliminated. The pixels are almost seamlessly connected, and the picture is integrated. Even when watching at a very close distance (such as the front row of the conference room, the control room), the pixel particles and scan line moiré are almost invisible, and the immersion is extremely strong.

- Ultra-high contrast: The flat blackened surface (or with ink-colored encapsulation glue) greatly reduces the reflection of ambient light, presenting a deeper black and brighter colors, and the picture layering is richer.

- Almost boundless vision: It is easier to achieve extremely narrow seams, and the visual sense of fragmentation is greatly reduced after splicing multiple screens.

2.Solid as a Rock, Leap in Reliability:

- Invincible physical protection: The thick overall encapsulation glue layer provides a strong physical barrier for the fragile LED chip. The waterproof, moisture-proof, dust-proof, bump-proof and scratch-proof performance far exceeds the SMD screen. The chip will not be damaged by finger pressing or hard objects scratching the surface.

- ESD immunity: The encapsulation glue effectively isolates the direct damage of electrostatic discharge to the chip, significantly reducing the risk of failure caused by static electricity.

- Ultra-low maintenance cost: The probability of failure of a single chip is extremely low, and after failure, the pixel points are tiny and covered by the glue layer, which is almost invisible to the naked eye, unlike SMD where a broken lamp bead is an obvious black spot. The "caterpillar" phenomenon and subsequent maintenance costs are greatly reduced.

3.Breaking Through the Density Limit:

- Get rid of the limitation of the physical size of the lamp beads, the bare chip can be made smaller and more densely arranged. COB technology is the mainstream and mature technology route for realizing ultra-small pitch displays below P1.0 (such as P0.9, P0.7, P0.4 or even smaller), meeting the high-end market's demanding requirements for ultra-high resolution.

4.Excellent Heat Dissipation Performance:

- The chip is directly attached to the metal-based PCB with excellent thermal conductivity, and the heat is quickly transferred to the back-end heat dissipation system through the substrate. Lower chip operating temperature means higher stability, longer life and better color consistency.

The Stage of COB Display: Defining High-end Visual Standards

With its Unparalleled Visual and Protection Advantages, COB Displays are Rapidly Occupying Scenes With Extremely High Requirements For Image Quality and Reliability:

- High-end command and control centers: power, transportation, emergency management (7x24 hours operation, zero fault tolerance, ultra-fine image quality).

- Enterprise conference rooms & boardrooms: close-up viewing without graininess, first-class experience for conference presentations and video calls.

- Broadcasting studios & virtual shooting: as background walls, accurate colors, seamless splicing, no moiré, meeting demanding film and television production requirements.

- Luxury retail & brand showrooms: extreme image quality perfectly presents product details and brand tone, enhancing the shopping experience.

- High-end conference rooms & hotel lobbies: create a shocking and immersive visual image wall.

- Medical imaging diagnosis: (scenes with strict requirements for high resolution, high contrast, and color accuracy).

- Future home theater (potential market): as costs fall and technology matures, it is expected to enter the high-end home market.

Challenges and Future: Continuous Improvement

Of course, COB Technology Also Faces Challenges:

- Cost: The current manufacturing cost is still higher than that of mainstream SMD products, but with the scale and process optimization, the gap is narrowing.

- Maintenance: Once the substrate or driver IC is damaged, the entire module needs to be replaced. It is extremely difficult to repair a single chip on site (but the failure of a single chip has almost no effect on the display).

- Surface consistency: The packaging process has extremely high requirements, and the flatness of the glue surface, the uniformity of the ink color, and the optical consistency must be guaranteed.

Future Development Direction:

- Continuous cost optimization: Improve yield and simplify the process.

- Pixel density breakthrough: The key bridge technology for the transition to Micro LED.

- Integration improvement: Deeper integration with driving and control technologies.

- Optimized optical performance: Higher brightness, wider color gamut, better viewing angle, and lower reflection.

- Curved & flexible form: Explore more possible applications.

Conclusion

COB LED display technology completely solves the granularity, fragility and density bottleneck of traditional SMD displays by liberating LED chips from "independent packaging" to "collective protection". It presents a natural and rock-solid visual experience, redefining the standard of high-end display. In the field of pursuing ultimate picture quality, seamless immersion and super reliability, COB is no longer a "future technology", but a "present tense" that is happening. When you are shocked by the silky and delicate picture in the high-end conference center, or see the stable picture that never goes out in the command hall, it is likely that the power of COB technology is behind it. It is not just a screen, but a door to the future of boundless vision.